Buffer Preparation & Storage

Buffer preparation is the process step where one flushes out materials and waste to regulate and control pH, which is necessary for developing your drug and storage. Furthermore, buffer prep is for the stabilization of reactions in different steps during the bioprocess.

For buffer preparation, one starts with mixing powder and fluid, like water. After doing this step, the mixed solution from the bag or carboy is brought to the bioreactor. The mixed solution can be transported using a pump or gravity and Single Use instruments such as flow, pH, pressure sensors, etc can be utilised to ensure everything is working correctly.

Assemblies for Buffer Preparation

- Single-use product transfer assemblies; transporting buffer to a reactor

- Single-use Buffer transportation assemblies

- Single-use bottle assemblies

- Single-use bag assemblies

Tubing

- Biopharmaceutical TPE tubing ; to create a sterile closed system for transporting the buffer to the bioreactor by welding.

- Silicone tubing: This is more common use in standard applications for transporting the buffer, you don’t have to weld.

- Pump-grade tubing has been developed for peristaltic pumps. It is designed to hold many hours of pump duration.

Bags

- 2D and 3D Single-use bioprocess bags are available up to 2000L and are designed for the preparation, storage and transport of buffers and biopharmaceutical solutions.

- 2D Rockerbag for cell culture applications.

- Cryo bags are available for up to 20L to store the biopharmaceutical products at -85°C.

Filters

- Sterilizing grade filters from Parker can be used for sterile filtration of your biopharmaceutical solution before transportation to the bioreactor.

Pumps

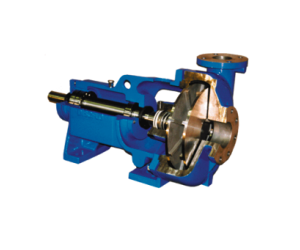

- The Quattroflow pump is a quaternary (4-piston) diaphragm low shear pump that enables gentle pumping through soft “heartbeats”. Each stroke of the four diaphragms is generated by an eccentric shaft, which is connected to the electric motor. This method of operation allows the Quattroflow pump to gently, safely and securely convey shear-sensitive aqueous solutions and biologic products with minimal impact. Compared to Single Use centrifugal pumps, the Quattroflow pump does not generate any heat. Heat generation can largely impact cell viability in critical processes. The gentle operations of the Quattroflow pump is ideally suited for these sensitive applications.