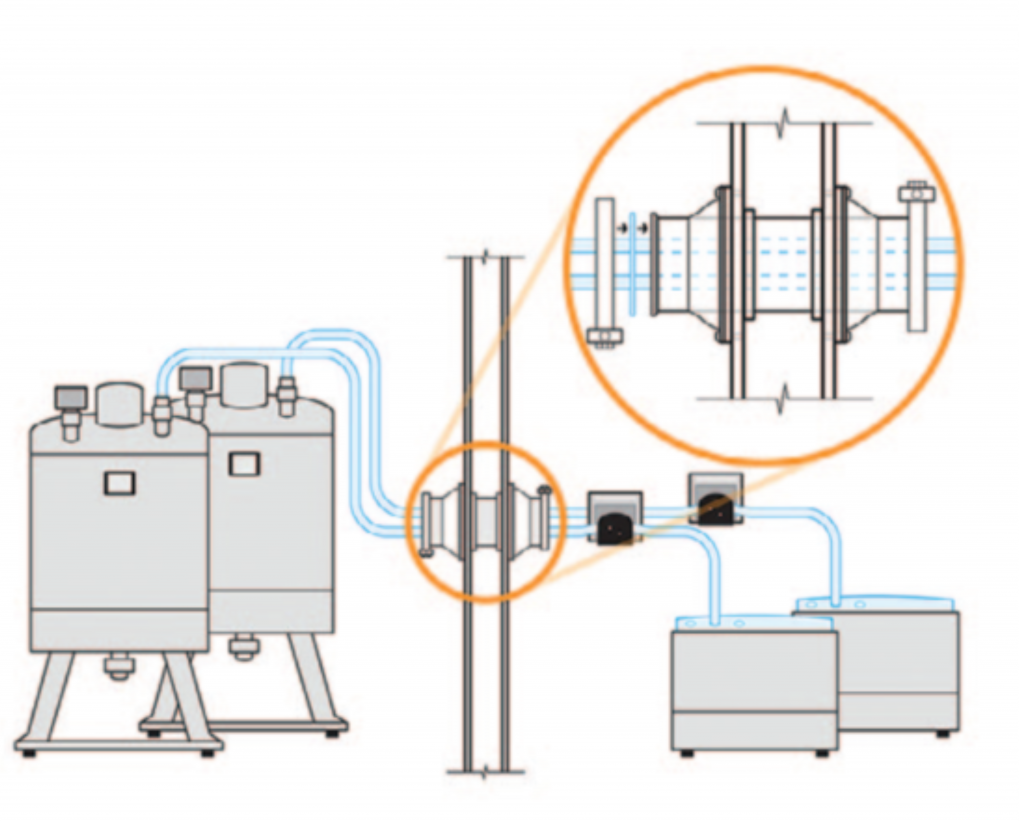

In pharmaceutical manufacturing, where sterility and efficiency are paramount, the AdvantaPass® Cleanroom Pass-Through System is a game-changer. AdvantaPass® allows the aseptic transfer of fluids between separate pharmaceutical suites while maintaining complete isolation between different cleanroom grades.

Designed to reduce cross-contamination, safety, reliability, and efficiency, this system is specifically engineered to accommodate single-use components and enhance cleanroom operations.

What Is AdvantaPass®?

AdvantaPass® is a patented cleanroom pass-through portal system that facilitates the sterile transfer of fluids between cleanrooms and bulkheads in pharmaceutical facilities. Unlike traditional pass-through methods, which involve manually moving equipment or piping between rooms and require frequent cleaning and validation. AdvantaPass® offers a streamlined solution. This technology enables the transfer of multiple fluid lines through a single stainless-steel portal while maintaining complete isolation and sterility.

Product Benefits of AdvantaPass®

- Elimination of Cleaning & Validation: AdvantaPass® utilises single-use disposable components, removing the need for cleaning and validating traditional hard piping transfer lines. This saves valuable time, resources, and labour that would otherwise be devoted to cleaning chemicals, sterilisation, and validation processes.

- Design Flexibility: Whether you’re constructing a new facility or retrofitting an existing one, AdvantaPass® offers design flexibility. It can be easily adapted and customised to accommodate different wall and floor thicknesses. The system can handle both single and multiple fluid flow lines without compromising isolation functionality.

- Enhanced Safety & Reduced Contamination Risk: One of the standout features of AdvantaPass® is its ability to transfer large volumes of liquid without the need to physically move bins or totes, eliminating the risk of breakage, spillage, and product loss. Purge ports further ensure limited cross-contamination between viral-active and non-viral-active suites contributing to a higher level of sterility.

- Custom Manufacturing for Specific Needs: AdvantaPass® systems are custom manufactured to meet the specific requirements of each application. Standardised components are paired with a variety of end connections, and the system is available in sizes up to 8 inches in diameter (with larger sizes available upon request). This allows AdvantaPass® to be tailored to the exact specifications of your cleanroom, providing maximum operational efficiency.

- Increased Productivity & Efficiency: The simplicity of AdvantaPass® assembly and disassembly – taking just minutes – allows for seamless transitions between production runs. This, coupled with its durable connection using 316L stainless steel, ensures minimal downtime and reduces the need for maintenance, further enhancing productivity.

- Eco-friendly & Cost-effective: By eliminating the need for cleaning validation, AdvantaPass® saves natural resources and reduces waste. With single-use process components made of high-quality materials like platinum-cured silicone or TPE tubing, pharmaceutical companies can avoid the expense of purchasing and maintaining hard piping systems. AdvantaPass® also helps reduce production stoppages due to sterilisation, resulting in significant cost savings over time.

AdvantaPass® ensures sterility across transfer processes, allowing manufacturers to focus on what matters most: delivering safe, high-quality pharmaceutical products to market.

AdvantaPass® ensures sterility across transfer processes, allowing manufacturers to focus on what matters most: delivering safe, high-quality pharmaceutical products to market.