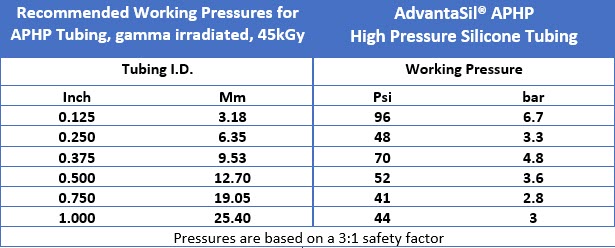

APHP High-Pressure Unreinforced Silicone Tubing is an alternative to Braid-Reinforced Silicone Hoses.

AdvantaSil APHP High-Pressure Unreinforced Silicone Tubing is a cost-effective alternative to braid-reinforced silicone hose, particularly where high system pressures are expected. APHP is suitable for many fluid transfer applications, including TFF, virus filtration, inline integrity testing of filtration assemblies, and high-volume fluid transfer.

See the chart below for pressures:

APHP’s key features include:

- Full vacuum capabilities on most sizes

- Flexible and translucent yet durable

- Meets USP Class VI, FDA, ISO and EP standards

- Complete validation package available

- Full BPOG standardised extractables test protocol has been performed

- Sterilisable by Autoclave/Gamma Irradiation

AdvantaSil® High-Pressure silicone tubing is a high-quality, cost-effective solution for increased flow rates to reduce processing time. It is optimal for Single-Use applications such as TFF, virus filtration, inline integrity testing of filtration assemblies, and high-volume fluid transfer.

APHP high-pressure silicone tubing has undergone extensive physical, chemical, and biological testing and meets USP Class VI, FDA CFR 177.2600, ISO 10993, European Pharmacopoeia 3.1.9, and other standards. A fully accredited, third-party test lab performed the full BPOG standardized extractables test protocol.

AdvantaSil High-Pressure tubing is not intended for implantation or continuous steam applications.

We offer a wide range of high purity tubing solutions including biopharma tubing, food tubing, chemical tubing and more. Discover our full range of tubing solutions or contact us for free expert advice now.