Concentration

Ultrafiltration (UF) and diafiltration (DF) are commonly used steps in downstream processing for product concentration and buffer exchange. A typical biopharmaceutical process uses three chromatographic column steps, each preceded by UF / DF of the product. Each UF/DF pre-treatment step is necessary to prepare the product for the following chromatography stage because all columns are operating under different pH or molarity conditions. The product needs to be primed for chromatography use beforehand. UF / DF concentrates and resuspends the product in the correct buffer before it is placed into the columns, this results in a faster and more efficient process.

Size is the basis of separation in filtration in most cases of UF/DF. The solution is contacted with the membrane under applied pressure. The applied pressure forces the solvents or buffers salts and smaller molecules to migrate through the membrane. While the membranes retain the larger molecules such as proteins, ultrafiltration operations can be performed in a tangential flow filtration (TFF) with cassettes or normal flow filtration (NFF). NFF could be carried out by dead-end filters or cartridge filters. These types of filters will retain the cells on the membrane surface or within the membrane structure.

Assemblies

- Transfer assemblies

- 2D bag assemblies

- TFF single-use assemblies

Tubing

- Platinum cured silicone tubing.

- Braided silicone tubing, specially designed for high pressure. Braided tubing can be placed in a high-pressure application or in front of a filter.

- Pump-grade tubing has been developed for peristaltic pumps. It is designed to have a longer pump life.

- Biopharmaceutical TPE tubing; to create a sterile closed system by welding 2 pieces of TPE tubing to each other.

Sampling Systems

- Sampling bottle systems are available from 60mL. The bottles are designed to take sterile samples of the product to check the quality.

- Sampling bag system from 50mL. The bags are designed to take sterile samples of the product to check the quality.

Bags

- 2D and 3D Single-use bioprocess bags are available up to 2000L and are designed for the preparation, storage and transport of buffers and biopharmaceutical solutions.

- 2D Rockerbags for cell culture applications.

- Cryo bags are available for up to 20L to store biopharmaceutical products at -85°C.

Filters

- Prefilters (as built-in or separate) are designed to remove products from the solution.

- Sterilizing grade filters have been specifically designed for the effective and economical processing of difficult-to-filter solutions.

- Cartridge filters.

- TFF single-use hollow fibre filters provide maximum crossflow performance with minimal preparation and installation time.

- TFF cassettes to build a complete single-use TFF system for the UF/DF steps.

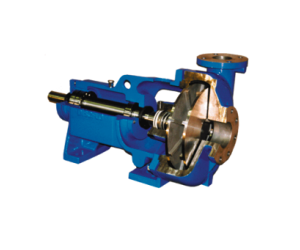

Pumps

- single-use/multi-use with magnetically levitated bearing less motor technology can be used to create a flow. This flow can be measured by single-use sensors, which can be connected to monitor the pump.

Plastic Fittings & Connectors

- Sterile connectors are an alternative to welding and sealing.

- Bioprocess Couplers/fittings are a solution to connect tubing to tubing or to connect tubing to the bioreactor. These couplers can be used to make your single-use assembly.

Valves

- Pinch valves can be used to shut off some directions of the fluid path. They are very useful in UF/DF steps.

- Fluid management solutions in single-use systems. It can be used to modulate and control flow automatically. It can also be implemented in customized single-use assemblies as a safety factor.

Instrumentation

- Inline single-use sensors used to monitor pressure, conductivity, pH, Temperature and turbidity.

Custom Plastic Equipment

- (Customized) Plastic totes and charts to build for the single-use bag.

- Roller Dollies.

- Funnels.

- Diptubes.