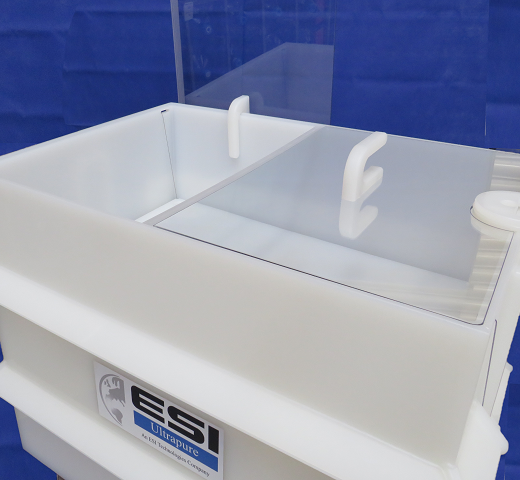

Product

Custom Plastic Equipment

ESI Ultrapure with Non-Metallic Solutions (NMS) works with customers to design the best custom plastic solution for your unique process.

We deliver a wide variety of custom solutions including; bag totes, process deployment carts, bottles, dip tubes and many other accessories for the Biotechnology and Pharmaceutical industries.